Table of Contents

Seamless user interfaces for every surface shape

The plastic electronic all-in-one circuit carriers were developed exactly for this purpose: To enable seamless integration of device operation in almost all surface forms.

3D formed surfaces

All-in-one circuit carriers with flexible printed circuit boards, for example, have the advantage that they can be formed into 3D shapes and can therefore also be seamlessly integrated into complex device surfaces.

Plane 2D surfaces

Conventional rigid circuit boards are mainly used when operating devices on a flat surface. These rigid circuit boards can be implemented very cost-effectively. They can be laid out in multiple layers with vias and thus have the advantage of being suitable for even more complex circuits. For flat surfaces, with the right technology, rigid and inexpensive PCBs can be integrated into surfaces just as well as flexible PCBs.

Whether with flexible or rigid circuit boards. In any case, the layer structure of the plastic electronic all-in-one circuit carrier enables very flat solutions with the best functionality and outstanding optics. Especially used to achieve seamless user interfaces for very special devices.

Perfect light in a thin construction

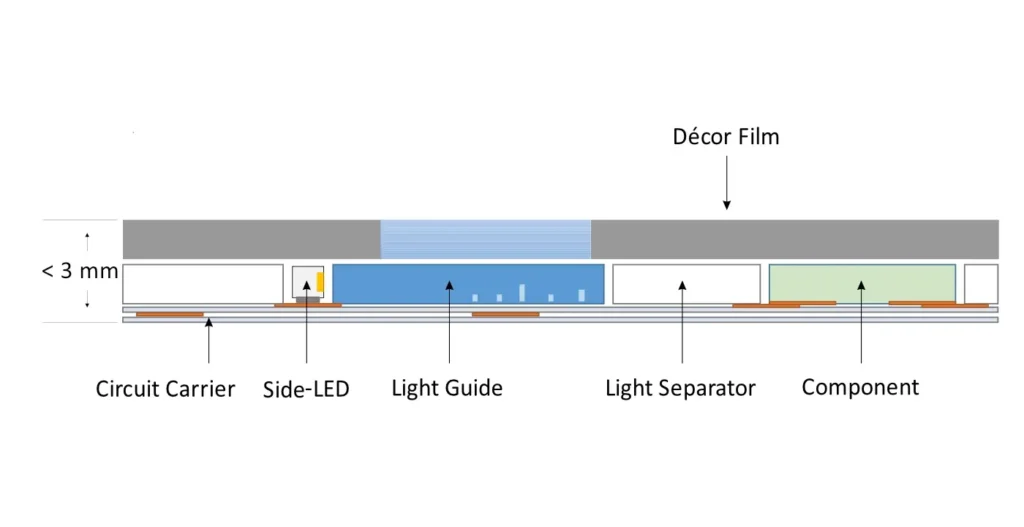

The core of every touch user interface is the lighting solution. Clean backlighting of the touch controls is based on a homogeneous illumination of the light elements, with sufficient light density and without spilling over onto neighboring elements. A good lighting solution naturally supports the simple and intuitive operation of a device. Additional ambient lighting such as light rings make the devices a visual highlight. All this can be realized in a thin and light all-in-one circuit carrier.

A seamless user interface for an impressive look and reliable protection

Undoubtedly, seamless user interfaces are visually very appealing and thus increase the value of a device. But the completely closed, seamless surface also has other advantages: It protects the inside of the device from dirt and moisture and is therefore easy to clean. To achieve this, printed decorative foils are particularly suitable as surfaces. In combination with thin layers for light management and the printed circuit board as a carrier for electronic components and conductor tracks, the optimal solution for a seamless user interface is created.

Processing by injection molding is also possible

Incidentally, the plastic electronic all-in-one circuit carriers can also be processed by injection molding if required. The technology used is the film insert molding process. The approximately 3 mm thick all-in-one circuit carriers are placed in the mold and partially back-injected. In this way, the user interfaces can be provided with the necessary support and fastening structures.

Tips for designing the user interface

If you now want to know how you can best design the seamless user interface for your individual device operation, then simply download our free plastic electronic Design Guide. You will find valuable and practical information in it.

Example: Device operation and device control in a flat structure

A touch user interface for the product RE.GUARD was developed together with the customer WimTec. In this project, not only the device operation but also the entire electronics for the device could be implemented on a flat user interface in a very thin structure. This efficient solution was made possible by using a rigid printed circuit board in a plastic electronic all-in-one circuit carrier. Decor, light and touch operation included.

Example: 3D molded washing machine console

The washing machine control panel integrates electronics, touch sensors and background lighting in an all-in-one circuit carrier that is less than 3 mm thin. The device controls blend seamlessly into the 3D surface of the washing machine. In addition to the outstanding appearance, the tightness of the seamless surface is also an important criterion for the manufacturer of the washing machine.

The operating concept is particularly noteworthy. The black panel effect enables a new and particularly intelligent user interface. Those operating functions that cannot currently be used are not visible. They are only illuminated when you can actually activate them. Unimportant things remain in the dark. The good overview guides the user intuitively through the process and leads to an optimal operating experience.